The Benefits of PolyVent

If you have livestock or agricultural buildings that would benefit from a brighter, quieter and more efficient heating and cooling system, our PolyVent and RidgeVent solutions are right for you.

How does it work?

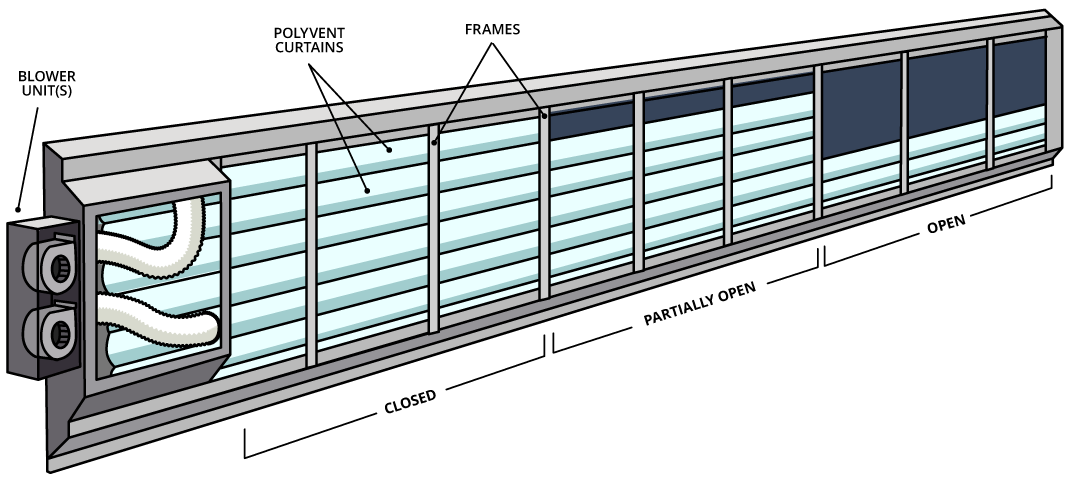

Thermostats control the blowers which inflate the PolyVent curtain. When the temperature inside a building gets above the desired temperature for the building, the bottom blower will shut off, causing the bottom tubes in the JanAire PolyVent curtain to slowly deflate and collapse into the bottom gutter, out of the way. This action creates a small top opening that allows for fresh, outside, air to enter the building. When more ventilation is called for, the top blowers will automatically shut off. The remaining tubes will partially, or fully collapse until the desired temperature is reached. PolyVent is a very active system when weather takes wild swings during the spring and fall. A 5 foot by 100 foot JanAire PolyVent curtain takes less than two minutes to transition from open to closed!

PolyVent II Overview

We call our inflatable curtain a PolyVent. A PolyVent II curtain resembles an inflatable air mattress propped up on its side and encased in a metal frame. A small, 1/40 th, 50 watt squirrel cage blower is connected by a flexible hose to the top tube of the “mattress”. As the blower fills the tubes with air, the”mattress” starts to rise, eventually filling the opening in the building behind the PolyVent II. PolyVent II is normally used on the bottom half of a stacked JanAire unit in dairy barns and is usually operated with an on/off switch.

PolyVent III Overview

PolyVent III is operated with two blowers. It has a special seal in either the second or third tube from the bottom of the poly. PolyVent III operates with two 1/40th, 50 watt squirrel cage blowers. One blower is connected to the top tube of the poly. The second blower is connected to the tube just below the solid seal on the poly curtain. Both blowers are connected with flex hoses. PolyVent III is used by itself on hog and poultry barns or in the top section of a stacked JanAire unit on a dairy barn.

RidgeVent Overview

Automatic with vinyl bladders

The concept of natural ventilation has been around for a long time. Everyone knows that hot air rises. The problem has always been how to regulate the amount of hot air passing through the ridge of a structure. In the past, various manually operated systems came and went, they just didn’t work well. Most of them shared two common faults: installation required extensive remodeling and farmers were totally responsible for the operation. Farmers had to guess where to set the ridge opening every time the wind or temperature changed. If they didn’t adjust the ridge correctly, they faced wide temperature fluctuations in the barn, and sick livestock.

The first automated ridge vents weren’t much better. They contained all types of expensive and troublesome apparatuses, including cables, pulleys, winches and actuators. Then the idea of using air compressors, electric pneumatic controls, and air cylinders came along. Farmers realized that those automated ridge vents were nothing more than a mechanical nightmare!

JanAire designed its RidgeVent to meet farmer’s needs: simplicity and automation. JanAire’s RidgeVent can be installed with a 5 inch wide single bladder, or two 10 inch or 15 inch wide double bladders.

How does the JanAire RidgeVent work?

A thermostatically controlled blower keeps the bladder inflated to maintain optimal interior conditions. When the sensor senses that ventilation is required, the blower shuts off to deflate the bladder. Excess warm air then rises freely through the ridge opening. The bladder in a JanAire RidgeVent is made from a durable 20 oz. vinyl, nylon material that will give you many years of dependable service. Our RidgeVents are built with an open design which means there is no cover over the top of the ridge vent opening. We do this because when naturally moving air turns a corner it loses half of its velocity. For example, a 10 inch wide covered ridge would move the same amount of air as a 5 inch open ridge. The sides of our RidgeVent are 11 inches in height which aids the venting effect when the wind blows across the ridge. The tall sides will also prevent wind driven rain from blowing up the roof and dropping into the opening. The maximum recommended length of our JanAire RidgeVent is 80 feet, but depending on the zone requirements, two 80 foot units could be driven head to head with one drive.

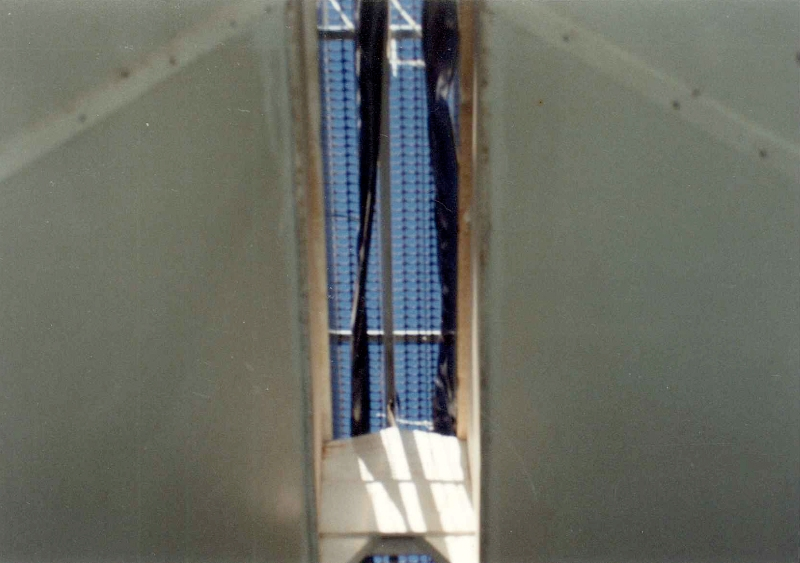

The photo below shows an interior view looking up through a 10 inch RidgeVent in the open position, allowing hot air to ventilate.

Choosing the Right Frame

Standard Frame / White or Galvanized

- Four sealing points ensure an air tight, draft free closure when the air curtain is completely closed.

- For all livestock species and all climate conditions.

- We recommend our white standard frame for hog barns. Our galvanized standard frame is suitable for most dairy and poultry installations.

- Constructed of 24 GA., 90 galvanized steel. Our white frame has a factory-applied Kylar paint finish.

- 10 year warranty on painted parts failure due to corrosion when properly installed in dairy and poultry installations.

- Our galvanized standard frame offers an 11% – 14% cost savings – depending on frame size – compared with our original standard white frame.

- The top gutter on a standard frame sheds rain and snow on barns with little or no roof overhand, or, on the end walls of dairy free stall barns.

Econo Frame / White or Galvanized

- White Econo Frames offer a 9% – 23% cost savings, depending on frame size, compared with the JanAire White Standard Frame.

- Galvanized Econo Frames offers a 21% – 39% cost savings, depending on frame size, compared with the original White Standard Frame.

- Three sealing points ensure a sufficient closure on warm barns located south of US Interstate 80 or in cool or cold barns located anywhere.

- We recommend at least a 2′ roof over hang on buildings for the Econo framed unit – this will ensure that rain water won’t get behind the curtain and into the barns interior.

- Econo frames have “J” guides attached to the bottom gutter every 4 feet the entire length of the vent opening.

- Econo frames do not include a top gutter.

Fail Safe Curtains

Over the years, a number of our JanAire customers have asked us to design a “shorter” version to be used especially as a “Fail-Safe” unit on power ventilated buildings. This “Fail-Safe” unit would be used as a safety precaution in the event of a power failure, thereby reducing the chance of your animals suffocating in a power ventilated building during a power failure. One important feature that hog producers have always approved of is that in the event of a power failure, the unit will always open … GUARANTEED!

Hog producers have reported a number of problems with the current fail safe devices on the market, including jamming shut, freezing up, and also problems resetting units after a power failure. The unique air bladder design of a JanAire curtain system eliminates these problems. Plus the unit acts as a window to allow sunlight to light up the area, even when it is closed. The smallest JanAire “Fail-Safe” unit will provide a 4 square foot opening at a cost of about $400 per unit. In comparison, a 32 square foot unit would cost $600. We will customize any size you need, with the smallest Fail Safe unit being 4 square feet of opening.

Holding Areas

When the holding area is empty, the ridge and side wall curtains are closed. The thermostats that control them are toward the front of the holding area on either side, suspended above the crowd gate fence. As the cows start to fill the area and generate some excess heat, a thermostat will tell the RidgeVent to open. If more air is called for, the thermostats will tell the appropriate JanAire curtains to open. As the area begins to empty out, the temperature begins to drop and the JanAire curtains start to close. If there is a strong cold wind from one side on the area, the thermostats on that side will tell the curtain to adjust.

Advantages

Often, with manually operated curtains, the workers in the pit get blasted by cold air between groups of cows, or when there are only a few cows left to be milked. So, the workers don’t open the curtains enough for good ventilation because of the cold drafts they get when the area is empty. With sufficient insulation in the ceiling or roof, and JanAire curtains on the side walls, you won’t need to add heat to the floor, which has been done in the past on some dairies in the colder parts of the country.

Testimonials

“The natural light is a game-changer…I’ll never go back and work in one of those dark brewed barns again!”

“We saved 75% on our propane bill when we switched to JanAire PolyVents.”

“With conventional curtains, our litter would go “out of condition” along the outside walls. Now it stays dry even with our coldest Minnesota winters!”

“There is no noise or drafts coming through…It’s an air-tight wall!”